CNC Machining

CNC machining is one of the most widely used engineering processes, but also the most flexible.

You can implement customized machining, low volume manufacturing and full production planning in one way.

What is CNC Machining?

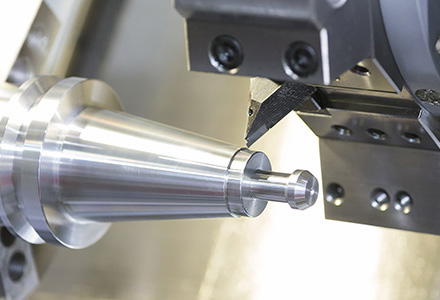

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. Common CNC machines include 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers. It includes CNC milling, CNC turning, and turn milled and more manufacturing methods.

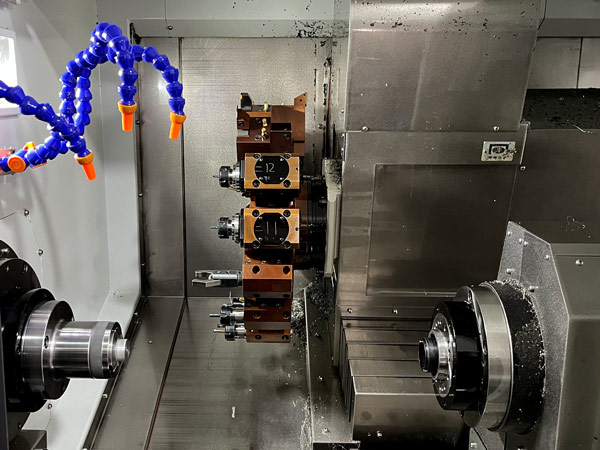

DOMI CNC Machining Workshop

The Advantages of CNC Machining

CNC machining is a very popular manufacturing method, which nearly all manufacture, agriculture, medical, and every industry in between, like to choose this process to make their products. The advantages of the milling and turning services are included but not limited:

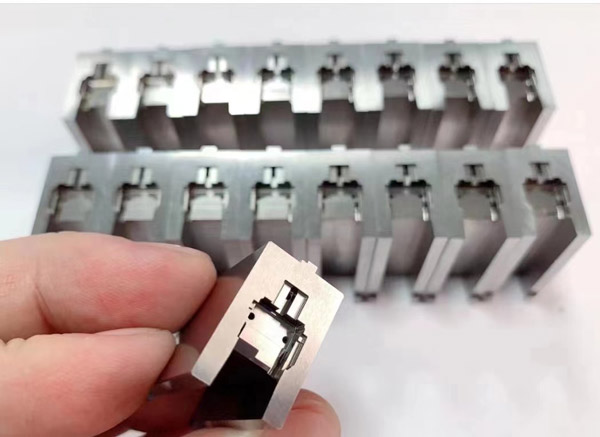

- The machined parts are made by the computer numerical control. Most machining errors can be calculated by the computer with some advanced programs. So compared to the traditional processes, it’s excellent to get the accurate milled and turned parts.

- Ideal way to bridge the prototyping and production. You can make your part by the CNC lathe for 1 part or thousands of or even hundreds of thousands of parts. And they are all just using the same programming.

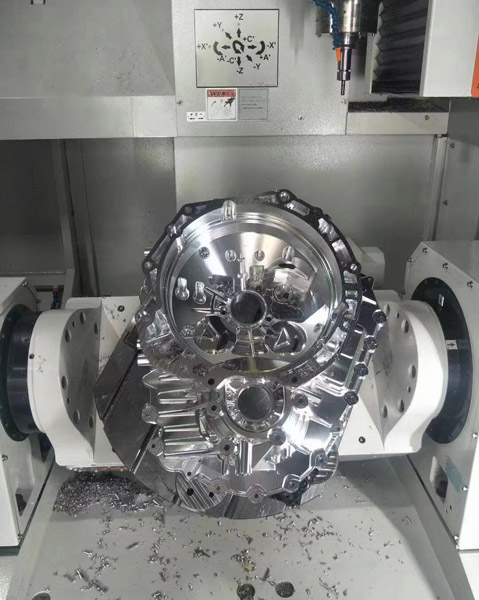

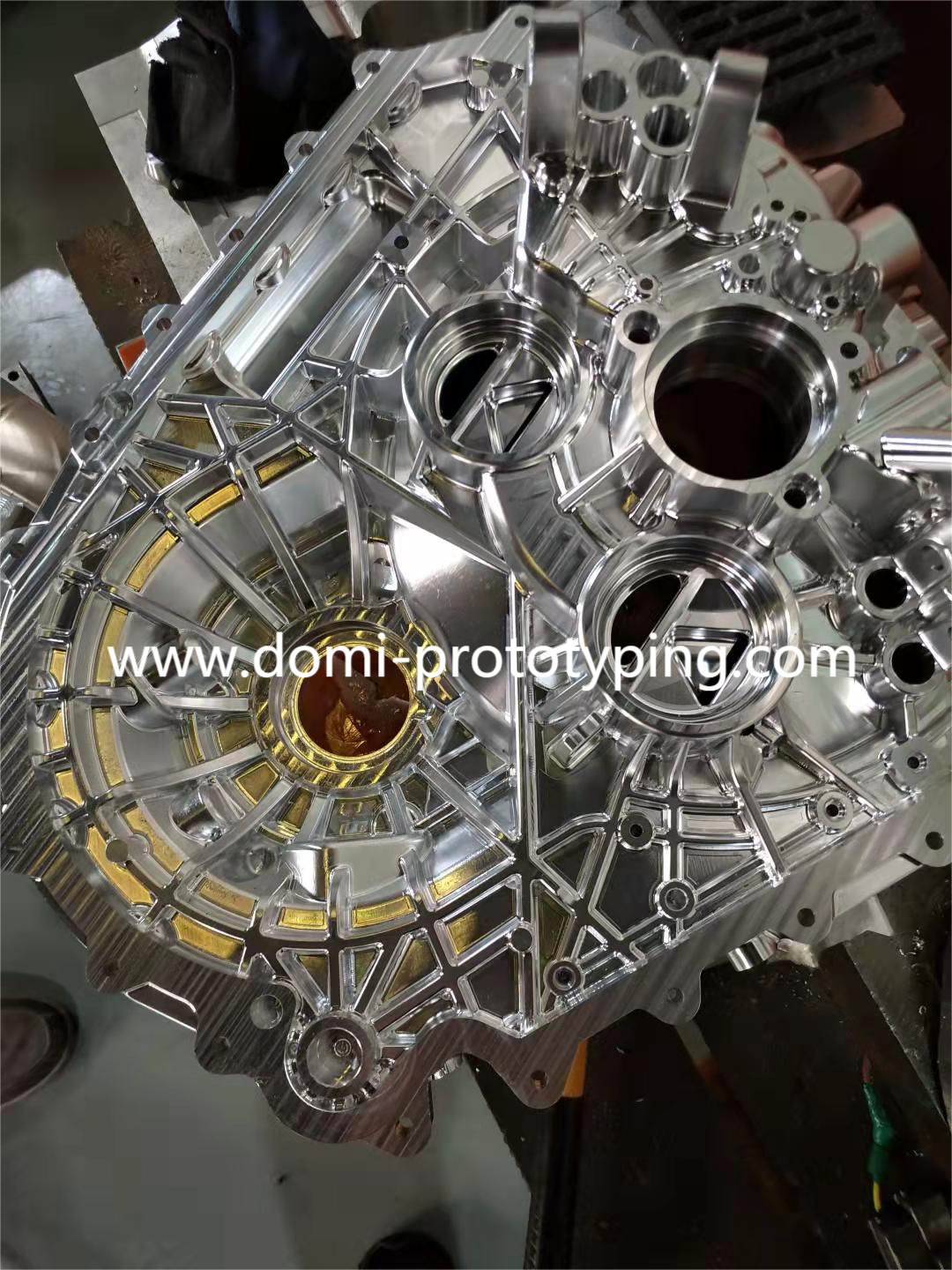

- CNC machining allows you to make a complex shape and texture which is impossible to produce the conventional machines and methods. That is, when CNC machines are used in tandem with advanced design software, of course. Digital software allows you to accomplish what not even the most gifted engineer can.

When Should You Consider CNC Machining?

Compared to traditional machining, CNC machining can be quite costly when it just makes several parts. However, it becomes much more cost-effective, however, when producing mass quantities of a product. Another time when it would make sense to choose CNC machining over conventional would be if consistency and precision are critical for the product you are manufacturing. This is where CNC truly shines, because the slight variations in products from human error are greatly minimized when the use of computers comes into play. In fact, CNC machining makes it possible to achieve accuracy within 1/1000th.

How’s the CNC Service in DOMI?

DOMI Prototyping has full experience of CNC machining. We have many production lines, such as CNC lathe area, turning area, turn-mill machining area. It includes 3 axis, 4 axis, 5 axis and other more advanced machines. We always provide sincere service and best quality to our clients. Expert team with engineering communication. Understand what you care about in the design and project. We have the capability to keep the complex part in a very tight tolerance. DOMI has invested a lot in machine upgrades and purchasing advanced programs.

CNC Lathe Available

DOMI Prototyping has different cnc lathes for your different machining requests. We make your parts as the designs by turning, facing, boring, drilling, knurling, chamfering, parting off, grooving, forming, taper turning, threading, reaming and tapping.

| 5 Axis Machine | Most flexibility and efficiency. Fit for the production that are a wide range of precise and very complex parts like car molds, artificial bones, military products and aerospace parts. |

| 4 Axis Machine | It has relatively tighter tolerance and is held between features on different sites of the workpiece. |

| 3 Axis Machine | It’s better suited to the manufacturing of planar milled profiles, drilling and threaded holes. |

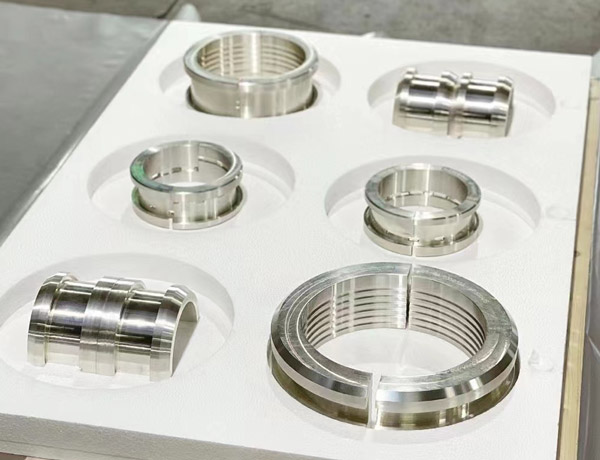

CNC Parts We Made

Materials Availabe

| Plastic Production | Metal Production |

| ABS, PC, PP, Nylon, ABS/PC, POM, Delrin | Aluminum, Alloy Steel, Copper, Brass, Stainless Steel, P20 Tool Steel |

Ready to Get CNC Machining Started?

DOMI Prototyping

DOMI has 30+ years of prototyping experience. We have seen the market change and have grown to meet the demands. We value experience and expertise, which is why the final product we deliver is precisely what our clients requested.