Rapid Prototyping

Rapid prototyping is a crucial step used throughout the product development process.

In this process, your concept can be optimized, you are more close to your success.

What is Rapid Prototyping?

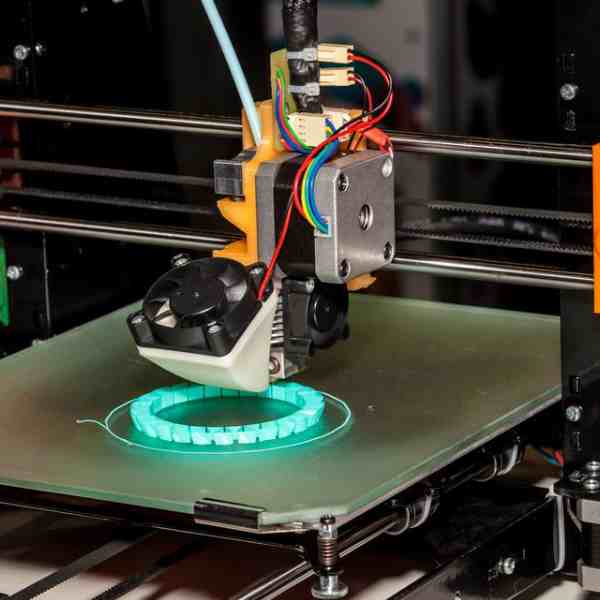

Rapid prototyping is a fast manufacturing process for 1 to several parts in a very short lead time. It’s a common early step in the product development process that quickly optimizes an initial design. It used real material, Implement most of the functionality of the product. Typically, speed is of most value during this phase of product development, so quick-turn or digital manufacturing processes like 3D printing, vacuum casting or CNC machining are preferred.

The Advantages of Rapid Prototyping

Rapid prototyping is a convincing manufacturing way. The primary advantages show in 3 points.

First, it ensures the product or component fulfills its design goals since it can be validated through user feedback or functional testing.

Secondly, all prototyping processes are fast manufacturing processes. The faster you receive the part to optimize it, the better benefit for your whole production development plan and scheduling.

Last but not least, it helps minimize costs since teams do not need to make the capital investment into tooling or manufacturing equipment that would be needed for a production run of parts.

How DOMI Support You

DOMI Prototyping is your stable supply and stable quality source. We would like to communicate with you about the project details to help you get a better solution. Find the best machining method to get your parts done.

- Send us your design file. We could give you the best advice with our skilled experience.

- Make quality parts in a short lead time. We have one stop manufacturing factory to support us to make all processes consistent.

- Have engineering communication logic to understand your requirements and insists.

How to Choose Rapid Prototyping Process

There are dozens of ways prototypes can be made. As prototyping processes continue to evolve, product designers are constantly trying to determine which method or technology is best for their unique application. Here is a chart that might help you to understand.

| Process | Plastic Production | Metal Production |

| 3D Printing | Thermoplastic-like photopolymers, Nylon, TPU | Titanium, 304 Stainless steel, 361L |

| Vacuum Casting | ABS, PC, PP, Nylon, ABS/PC | |

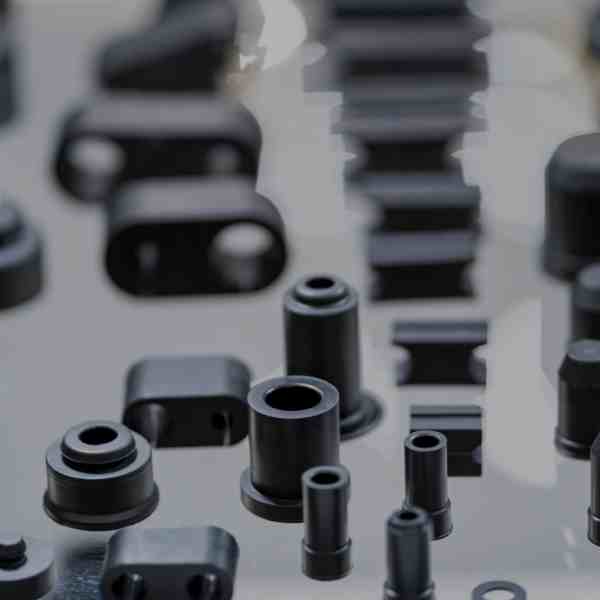

| CNC Machining | ABS, PC, PP, Nylon, ABS/PC, POM, Delrin | Aluminum, Alloy Steel, Copper, Brass, Stainless Steel, P20 Tool Steel, |

Material Options

Urethane Resins:

To make prototypes, a thermoset polymer gets poured into a mold.

Thermoplastics:

A form of plastic that can be melted and molded into precise shapes or 3D printed.

Metals:

Titanium, aluminum and steel are popular prototype materials.

Ready to Get Rapid Protoyping Started?

DOMI Prototyping

DOMI has 30+ years of prototyping experience. We have seen the market change and have grown to meet the demands. We value experience and expertise, which is why the final product we deliver is precisely what our clients requested.